|

THE MARK III:

The 750 Formula set out to be one of the least expensive in the sport of

car racing and in order to keep costs down the regulations made it

compulsory to use many Austin Seven parts like chassis, rear axle, engine

gearbox and propshaft etc. In addition the cars had to be road worthy and

capable of being driven to and from the circuit. Selling the Mark II to

trials driver Mike Lawson as well as dispossing of the Mark I, Colin was

in funds enough to buy an Austin Seven saloon for the basis of the Mark

III, and have money to start on the new project in Vic Williams’s lock-up.

No sooner had he started than he met the Allen brothers, Michael and

Nigel, two dental students who were neighbours of Hazel's and whose

parents had a very well equiped garage. In no time at all, Colin had

convinced them that what they wanted to do most was to make themselves a

Mark III Lotus each, to be built at the same time as Colin’s own, in their

garage!

CHASSIS:

The Mark III chassis was to be much stiffer than the earlier cars having,

instead of flat aluminium bonded plywood, additional tubes welded to form

a triangulated ‘cage’ bolted to the front ‘A’ frame. This cage needed to

be removed before any serious work could be done to the engine but this,

as it turned out, was a small price to pay for what was to be streets

ahead in chassis design terms, compared with the rest of the competition

in the 1951 750 Formula championship. As with the previous cars there was

a split Ford Eight beam axle with a flattened semi eliptical spring

providing independent swing-axle front suspension. A great deal of care

was taken to ensure that everything was as light as possible; in fact the

completed car only weighed 815lbs (370Kg).

TRICK ENGINE:

Whilst the body and chassis were far ahead of the other competitors, the

real success lay with the performance of the engine. By this, his third

year of competition, Colin realised that interpretation of the regulations

was all important in order to make a winning car. The 750 Formula rules

required the use of a standard Austin Seven side-valve cylinder block with

it’s ‘siamesed’ inlet ports. In other words the four cylinders and four

inlet valves were served by only two inlet ports. From a technical point

of view this was inefficient because with a 1-3-4-2 firing order the two

adjacent cylinders fired immediately after one another and would rob each

other of the correct amount of incoming fuel/air mixture.

Colin’s answer was to ‘de-siamese’ the ports, not by altering the

side-valve block, but by using a specially made four-piped but two-branch

manifold. Fabricated of sheet steel, the two rectangular-sectioned pipes

were each divided into two and this division protruded into the two

enlarged ‘siamese’ inlet ports within the block where they were ‘sealed’

in with asbestos strip. A hugh twin-choke Stromberg carburettor from a

Ford V8 was fitted! So to the casual eye it looked like a modified

two-pipe inlet manifold. Although no power output was ever documented, the

results were devastating as the Mark III simply ran away from everything

in it’s class that year. With a top speed of around 90 mph from a crude

749cc side-valve engine designed in 1922, most 5 to 10 lap races were won

by half a lap.

At the end of the season the inevitable happened; the rules got changed

and the following year ‘de-siamesed’ ports were banned! Successes on the

track meant that Michael and Nigel Allen’s cars were not going to be

completed as any progress on them was thwarted to keep Colin on the track.

It had been decided that Colin would be the driver in all the 750 Formula

Championship races whilst Michael, Nigel and occasionally Hazel would

drive in non-championship events. By the end of the season it was clear

that the arrangement they had wasn’t going to work and Nigel decided to

concentrate on dentistry.

|

Nigel and Michael Allen in the Lotus Mark III Castle Combe

2003.

Nigel and Michael Allen in the Lotus Mark III Castle Combe

2003.

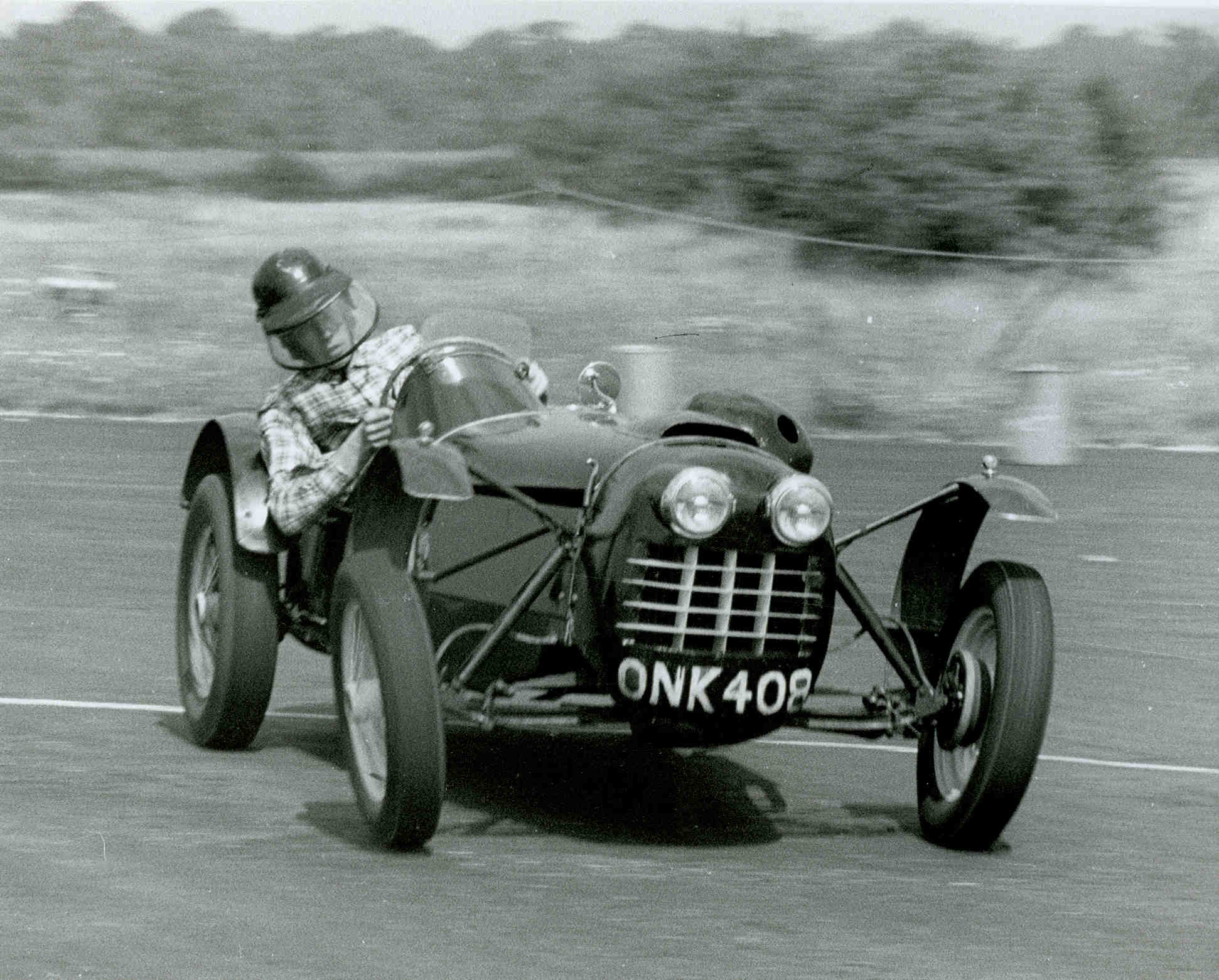

The Lotus Mark IIIb.

The Lotus Mark IIIb.

The Lotus Mark IV.

The Lotus Mark IV.