|

LOTUS SEVEN REGISTER |

the web site for the

Seven made by Lotus between 1957 and 1973

|

LOTUS SEVEN REGISTER |

the web site for the

Seven made by Lotus between 1957 and 1973

The very different Series IV chassis.

The very different Series IV chassis.

Factory Photo.

Factory Photo.

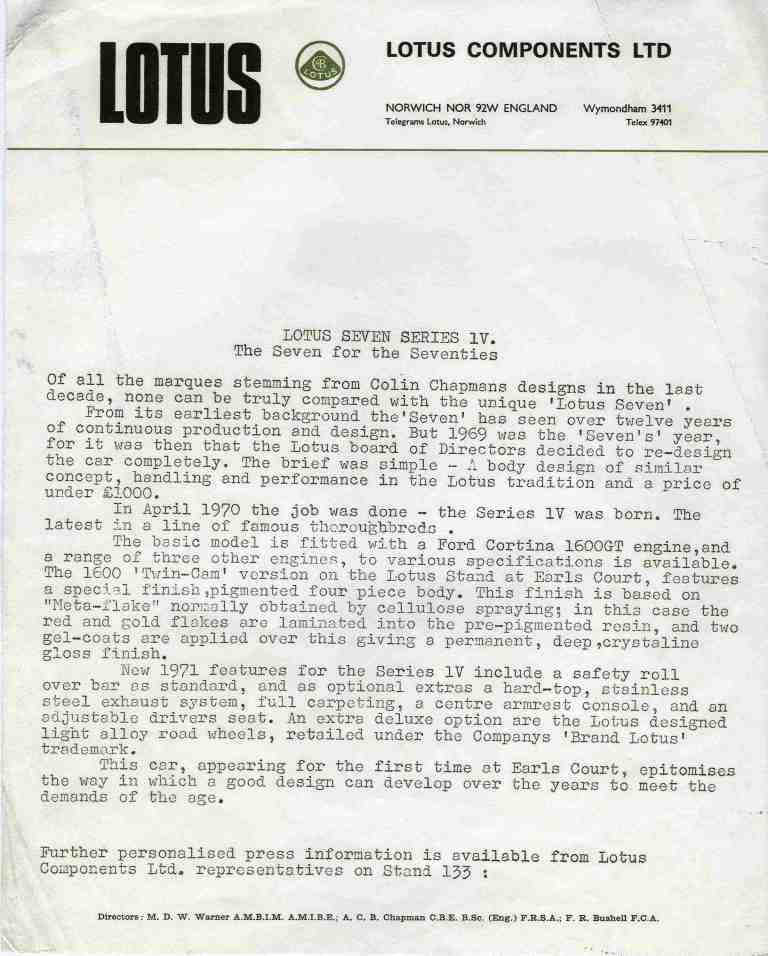

Series IV Factory Announcement.

Series IV Factory Announcement.

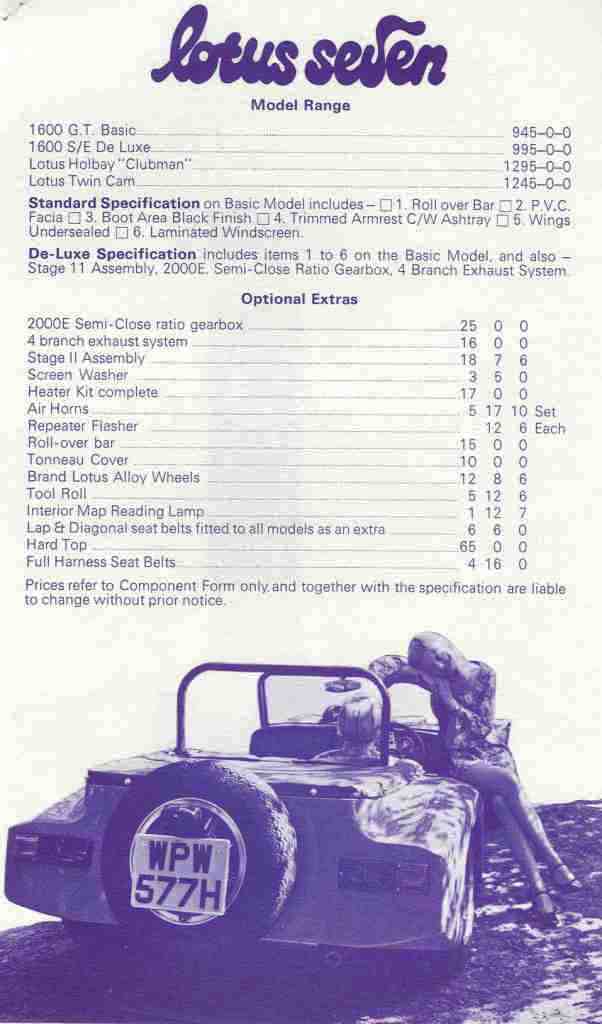

Price List from later brochure.

Price List from later brochure.

| [previous chapter] [next chapter] [back to menu] |