|

LOTUS SEVEN REGISTER |

the web site for the

Seven made by Lotus between 1957 and 1973

|

LOTUS SEVEN REGISTER |

the web site for the

Seven made by Lotus between 1957 and 1973

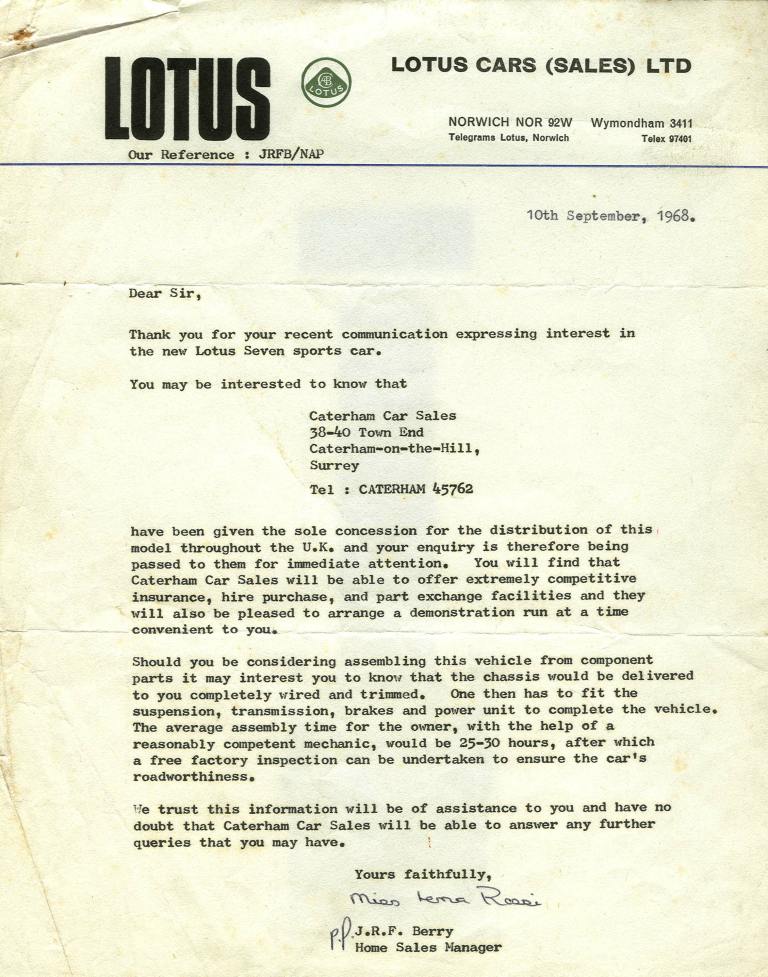

Letter announcing that Caterham Car Sales are to have

sole concession.

Letter announcing that Caterham Car Sales are to have

sole concession.

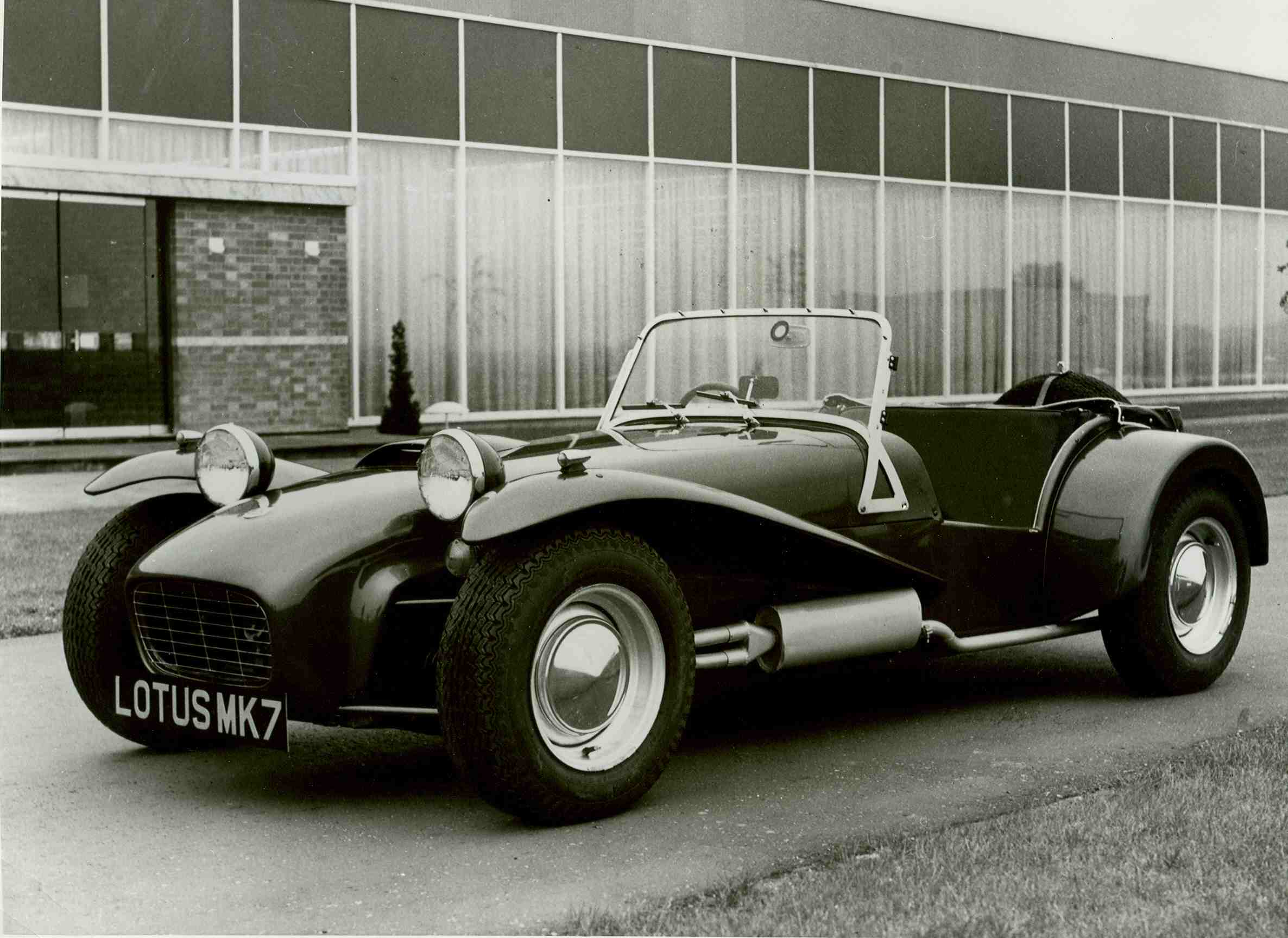

Official factory photograph taken at Hethel.

Official factory photograph taken at Hethel.

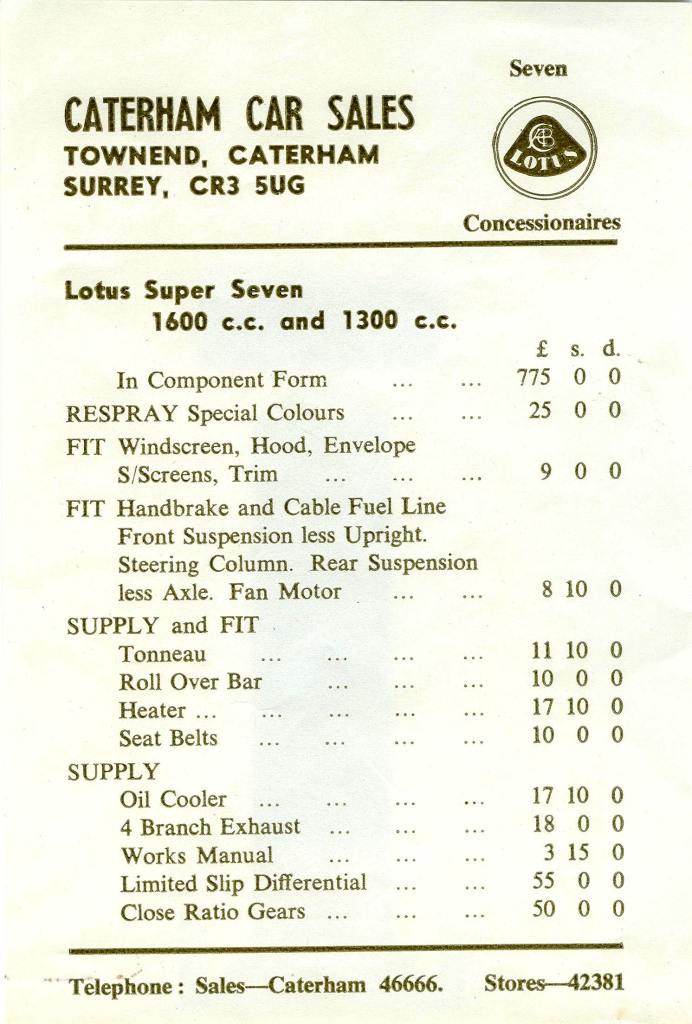

Caterham's Price List.

Caterham's Price List.

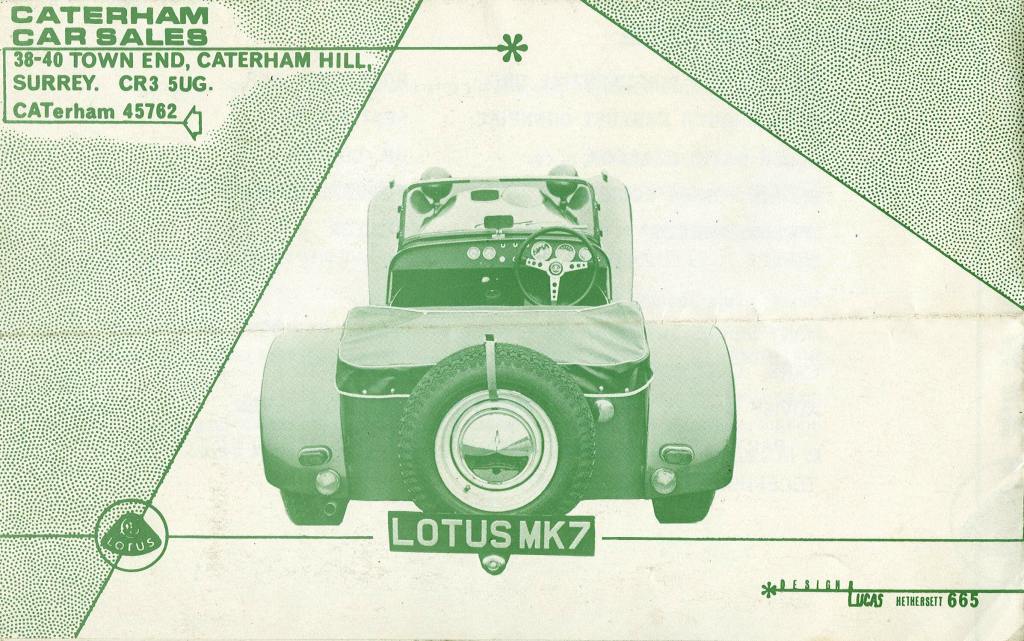

Caterham's Lotus Seven Brochure.

Caterham's Lotus Seven Brochure.

|